|

PDC

drill bits – shear rock with a continuous scraping motion Keys Bit PDC drill bits provide a drilling tool that uses polycrystalline diamond compact (PDC) cutters to shear rock with a continuous scraping motion. These cutters are synthetic diamond disks about 1/8 inch thick and about 1/2 to 3/4 inch in diameter. These products are offered in both a steel body and matrix body construction. Keys Bit PDC offerings include drill bits ranging in diameter from 7-7/8 in (200 mm) to 36 in (914 mm) in the steel body construction and 5-7/8 in (149 mm) to 17-1/2 in (445 mm) in the matrix body construction. Several different product lines are offered providing a highly efficient, cost effective solution for most drilling applications. Because the shearing action of PDC cutters are more efficient than the crushing action of a button or tooth bit, fixed cutters are in high demand. |

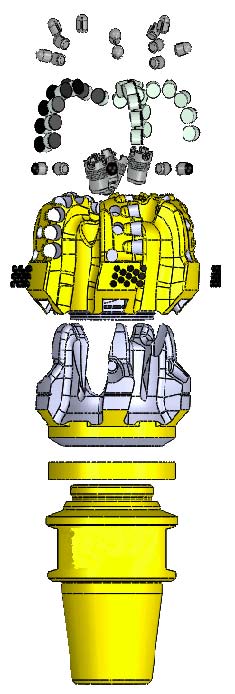

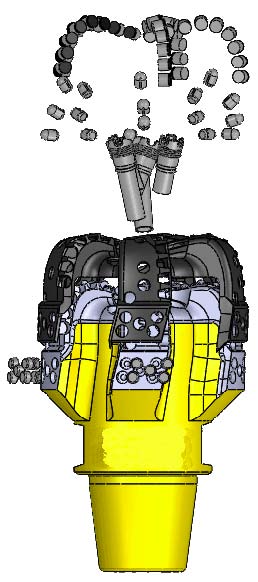

Above: Steel Body PDC

Left: Matrix Body PDC |

APPLICATIONS

The diamond drill bit is used in nearly all applications including geothermal energy drilling, mining, water well,natural gas, and oil well drilling. Total depths range from 100' to 20,000'.

LIMITATIONS

Impact damage, heat damage and abrasive wear all inhibit a drill bit's performance and can occur in even the softest geological formations. However, the most difficult formation for a PDC bit to drill are extremely abrasive ones. With PDC popularity on the rise, bit manufacturing companies are seeking new materials and design aspects to make a tougher bit without compromising ROP.

HOW PDC CUTTERS ARE MADE

Cutters are made using a combination of high heat and high pressure. Man made diamonds can be grown in 5-10 minutes. Because of this diamond content, a fixed cutter bit may also be known as a diamond drill bit. Cutters are made from a carbide substrate and diamond grit. A cobalt alloy is also present and acts as a catalyst to the sintering process. The cobalt helps bond the carbide and diamond. During the cooling process, the tungsten carbide shrinks at a rate of 2.5 times faster than the diamond. .

LARGE VS. SMALL CUTTERS

As a general rule, large cutters (19mm to 25mm) are more aggressive than small cutters. However, they may increase torque fluctuations. Additionally, if the BHA has not been designed to handle the increased aggressiveness, instability may result. Smaller cutters (8mm, 10mm, 13mm and 16mm) have been shown to drill at higher ROP than large cutters in certain applications such as limestone. Also, bits designed with smaller cutters but more of them can withstand higher impact loading.